About Us

We utilize high-grade composite materials that enhance durability, spin, control, and power.

Manufacturing Capability

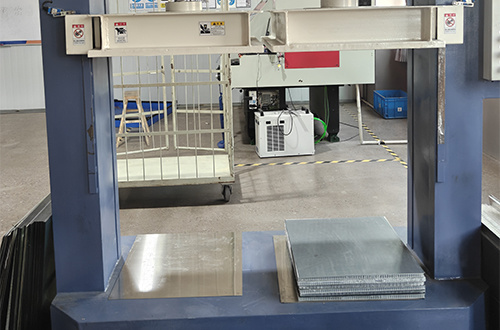

Material Preparation Machine

Precision mold stamping machines quickly form composite paddle frames, ensuring arc and hole accuracy for mass production of multiple models.

Positioning-equipped cutting machines precisely cut paddle carbon fiber, handle materials, etc., with smooth burr-free edges, compatible with multiple materials to enhance assembly efficiency.

Cold-pressed Equipment

Cold press uses hydraulic system for room-temperature compression, ensuring tight frame/shaft structures with enhanced strength and durability.

A high-precision CNC engraving and milling machine finely machines paddle surfaces for diverse designs and high-quality craftsmanship, boosting efficiency and quality.

Thermoforming Equipment

Hot press with temperature/pressure controls enables integrated frame/shaft molding through precise parameter adjustment, enhancing stability and rebound for mass production.

UV High-Precision Printer

The UV high-precision industrial printer with advanced nozzle control and UV curing prints complex logos, gradient colors, and wear-resistant coatings on paddle surfaces with vibrant, long-lasting results.

Company court

We love pickleball! With our company court, we play often and hold tournaments - great for team bonding and product testing.