About Us

We utilize high-grade composite materials that enhance durability, spin, control, and power.

Quality Control

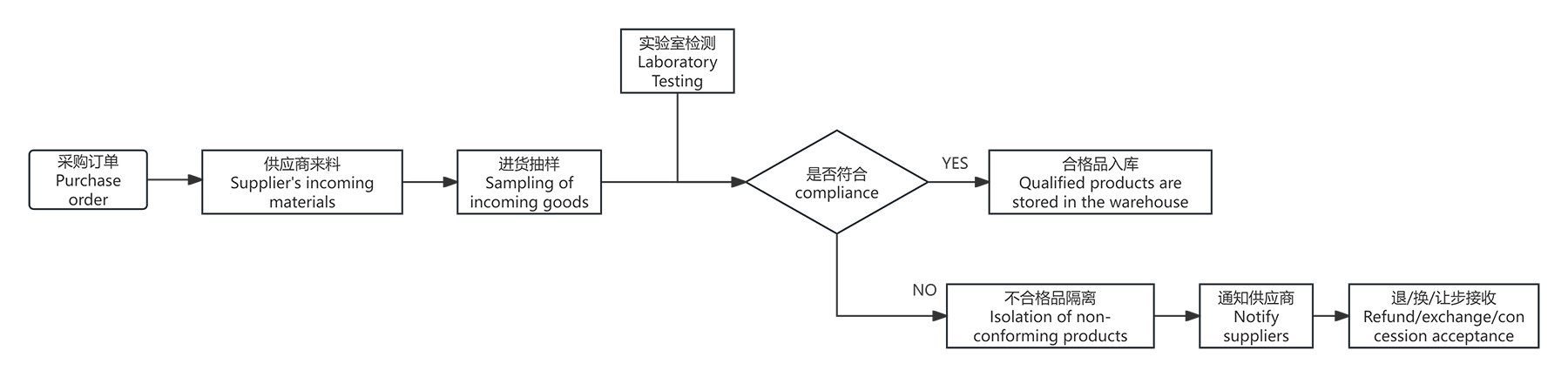

Quality Control - material

Quality Control - facilities and procedure

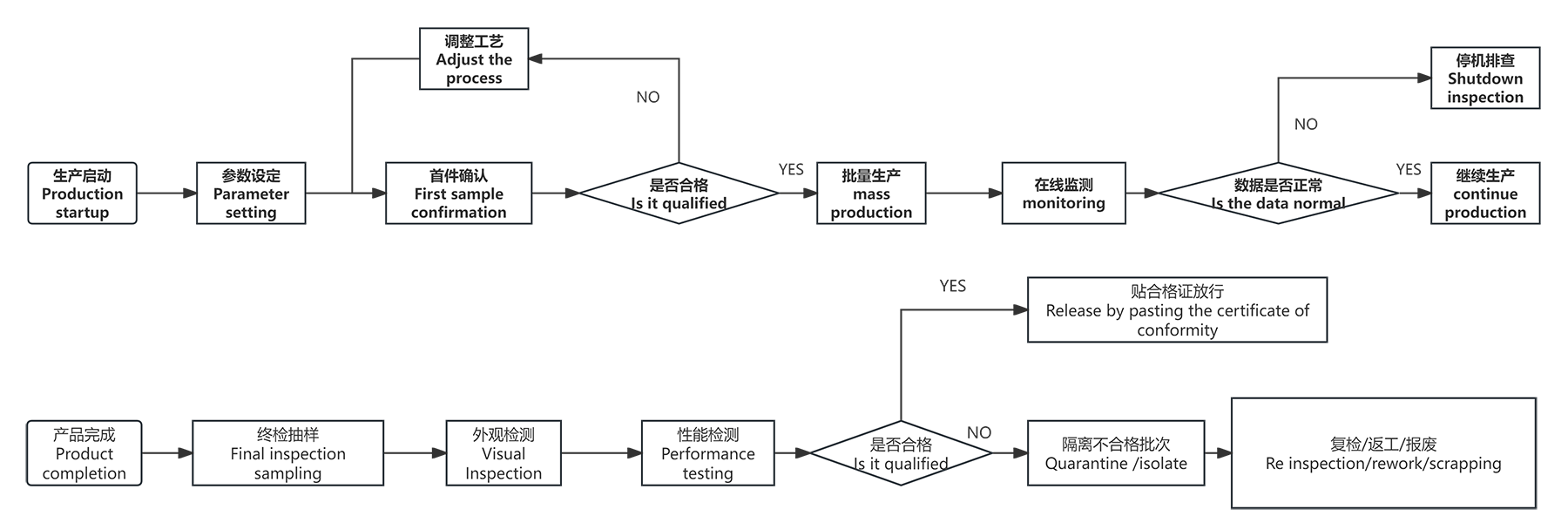

Quality Control - facilities and procedure

We have a complete range of production and testing equipment, with dedicated operating manuals for every machine.

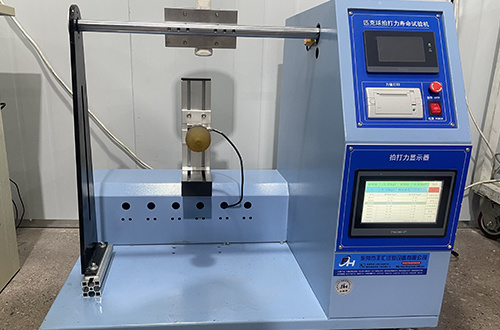

Testing Equipment

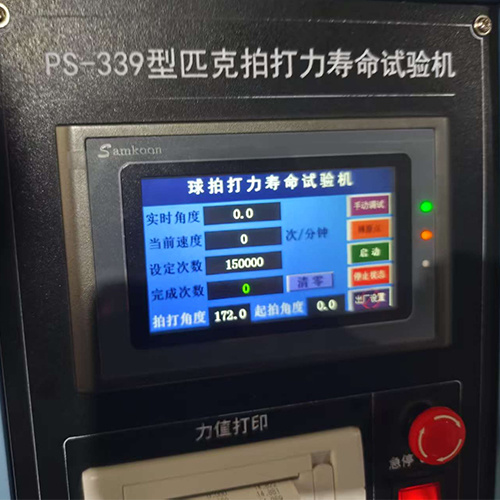

Our pickleball paddle tester integrates multiple functions to check key metrics including handle strength, balance, weight distribution and CoF, ensuring precise performance data for quality assurance

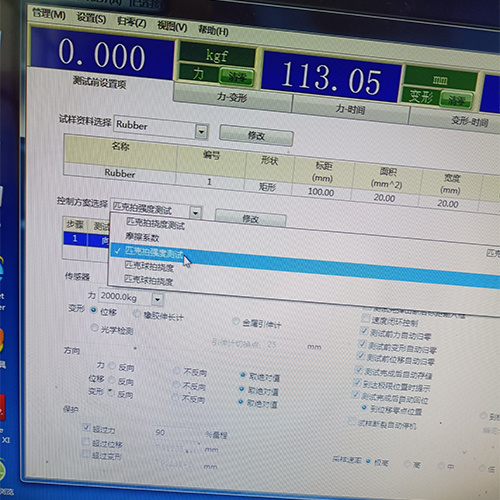

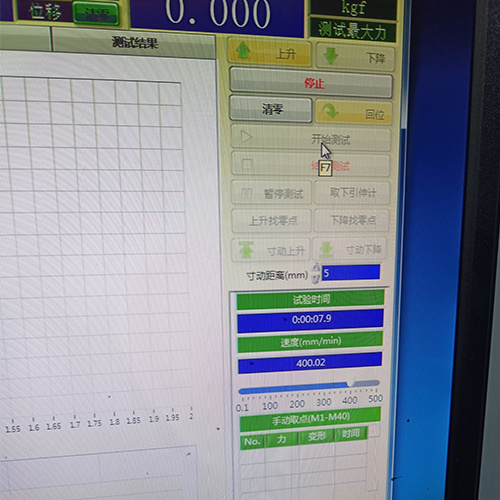

The paddle strength tester specializes in structural tests. Its pressure-sensing system performs impact tests to pinpoint weak spots, ensuring durability and safety

Quality Control - product testing

Paddle hitting test:

Set tester: 12-25kg force, 150,000 hits

Secure paddle, reset counter, start test

Check for delamination/hollows/dents - none means pass

Paddle handle strength test

1.Power on tester, select strength test in program

2.Assemble tool and adjust tester height

3.Secure paddle with handle centered under pillar

4.Reset data, begin test

5.Record results after testing.

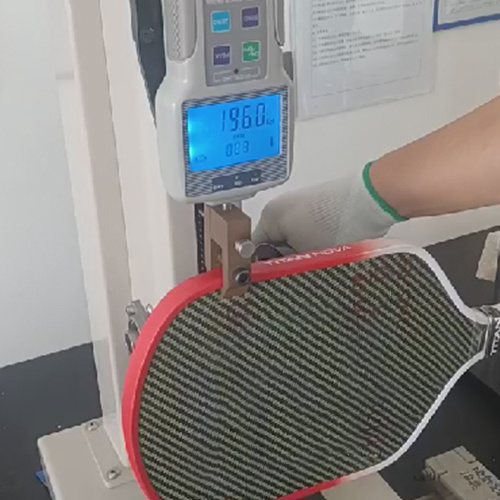

Edgeguard test

1. First, debug the jig/jig, and select the points that need to be tested.

2. Before testing, clear the data to zero.

3. Turn the machine slowly until the tensile force that needs to be tested is reached.

4. If the edgeguard of the paddle does not fall off, it is qualified.